Do you know the uses of linear guides?

Aug 28, 2025

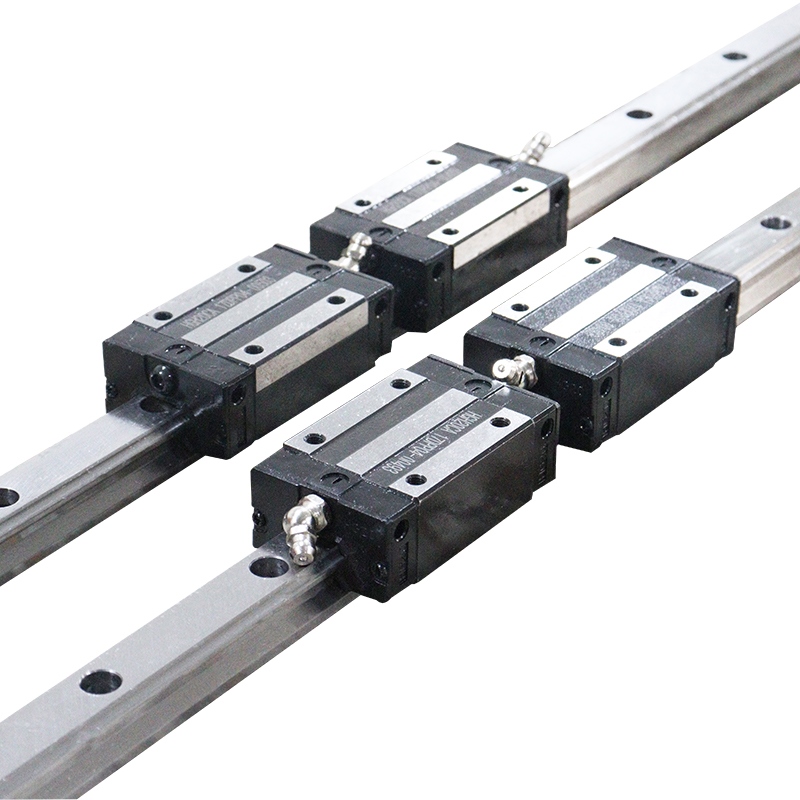

Linear guides have a wide range of applications. They are the "backbone" and "blood vessels" of modern industrial equipment and precision machinery. Their core mission is to provide high-precision, high-rigidity, and high-efficiency linear motion.

I. Core Application Areas

1. CNC Machine Tools - The "Main Field"

This is the most classic and important application area for linear guides. They directly determine the machining accuracy and speed of machine tools.

Purpose: Controls the movement of key components such as the turret, spindle, and worktable.

Specific Equipment: Machining centers, CNC milling machines, lathes, grinders, EDM machines, etc.

Function: Enables precise positioning and rapid movement of tools or workpieces in the X, Y, and Z axes, completing the cutting of complex parts.

2. Industrial Robots - "Flexible Joints"

Purpose: Serves as the robot's seventh axis (ground rail), extending the robot's travel distance and operating range. Used in linear motion joints within robot arms, they enable precise and smooth extension and retraction.

Function: Provides reliable basic linear motion for robots, widely used in robotic workstations for handling, welding, painting, assembly, and other tasks.

3. Electronics and Semiconductor Manufacturing Equipment - "King of Precision"

Purpose: Positioning and moving precision components such as chips, wafers, and circuit boards.

Specific Equipment: Semiconductor lithography machines, chip packaging machines, surface mount (SMT) machines, wire bonders, wafer probers, and LCD panel handling equipment.

Function: Achieving ultra-high-speed, ultra-precision positioning at the micron and even nanometer scales is crucial for the production of chips and electronic components.

4. Precision Measuring Instruments - "Fiery Eyes"

Purpose: Moving sensors or probes to scan and measure workpieces.

Specific Equipment: Coordinate Measuring Machines (CMMs), Image Measuring Machines, and Laser Scanners.

Function: Providing an extremely stable and precise reference motion track for the measuring head. Any slightest wobble will directly affect the measurement results, thus requiring the highest precision from linear guides.

5. Medical Equipment - "Lifeguards"

Purpose: Moving diagnostic or therapeutic components. Specific equipment: CT machines, MRI scanners, linear accelerators (radiotherapy equipment), surgical robots, and automated biochemical analyzers.

Purpose: Achieve precise patient movement or precise positioning of treatment equipment, requiring smooth, quiet, and reliable operation.

II. Other Common Applications

Automated production lines: Linear motion units in material handling, automated assembly lines, and logistics sorting systems.

Laser processing equipment: Guides the movement of laser heads in laser cutting and laser welding machines.

Printing equipment: Reciprocating motion of print heads in digital printers and large-format printers.

Aerospace: Used as simulation test platforms for components such as aircraft wings and missile servos.

Everyday items: Even high-end office furniture (such as height-adjustable desks) and smart home devices can be found in them.

To summarize its core applications:

Its ultimate purpose is to ensure that a component on a device is fast, stable, accurate, and able to withstand loads.

If you are interested in linear guides, please leave your information and I will contact you in time.

Network Supported

Network Supported