Why use CHUNXIN for customized online CNC machining services?

1. Quality assurance: The suppliers that CHUNXIN cooperates with have been strictly screened and audited and have high-quality processing capabilities. The platform also provides a strict quality control process to ensure that the processed parts meet customer requirements and specifications.

2. Multiple processing technology options: The CHUNXIN platform supports a variety of different processing technologies, including milling, turning, drilling, grinding, laser cutting, etc., which can meet the processing needs of different types of parts.

3. Rich resources: The CHUNXIN platform provides a wide range of material options, including metals, plastics, composite materials, etc. Customers can choose suitable materials for processing as needed.

4. Customized service: The CHUNXIN platform can provide customized processing services according to customer needs, from design documents to production and manufacturing, providing a complete service process, and fully considering customers' special requirements and design needs.

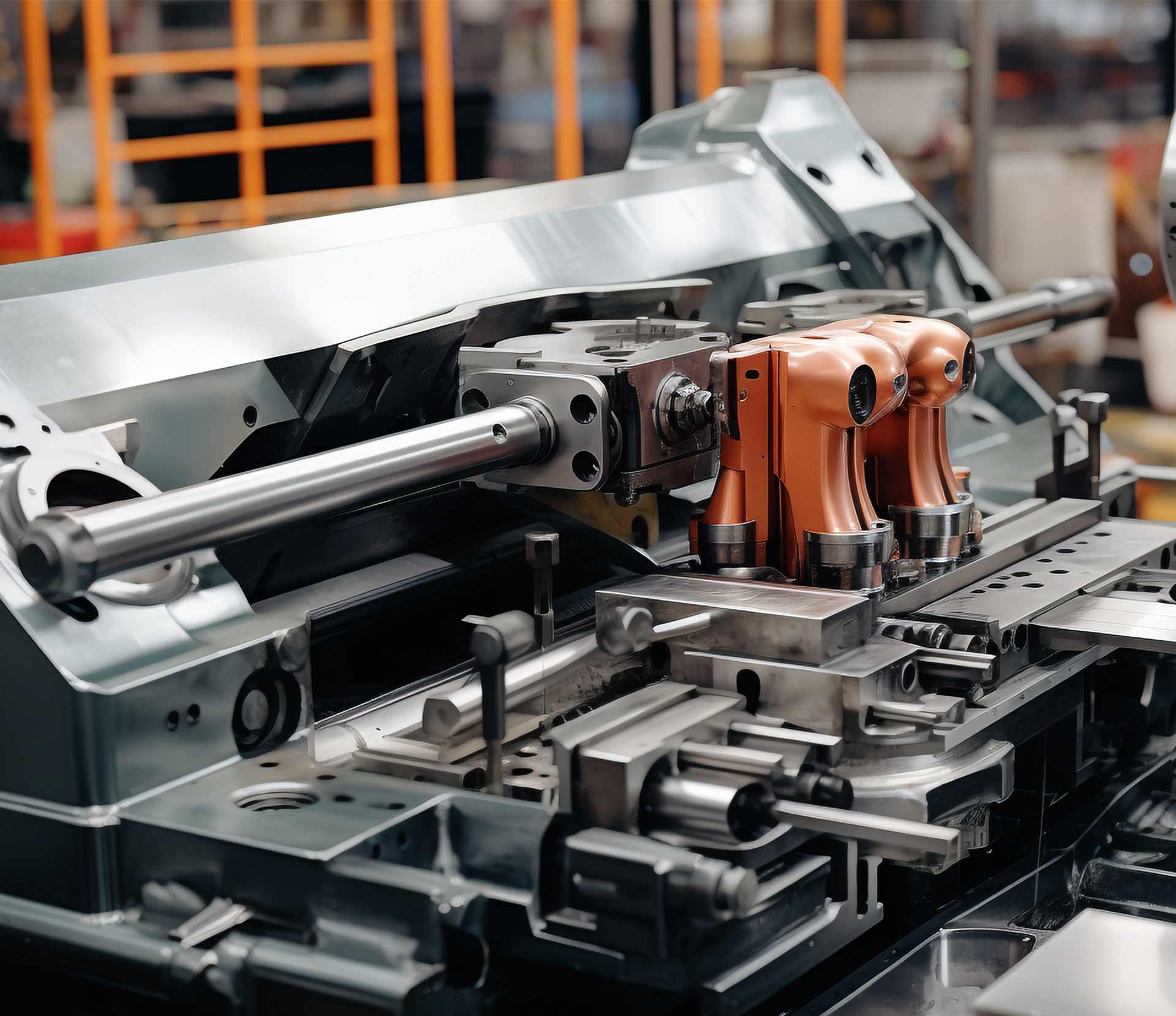

CNC Machining Capabilities

-

CNC Milling

CNC milling is a subtractive manufacturing process that uses 3-axis milling and 5-axis indexed milling processes to cut solid plastic and metal blocks into final parts.

CNC Milling

CNC milling is a subtractive manufacturing process that uses 3-axis milling and 5-axis indexed milling processes to cut solid plastic and metal blocks into final parts. -

CNC Turning

CNC turning with live tooling combines both lathe and mill capabilities to machine parts with cylindrical features from metal rod stock.

CNC Turning

CNC turning with live tooling combines both lathe and mill capabilities to machine parts with cylindrical features from metal rod stock. -

CNC Routing Services

Get quotes on custom parts with our Online CNC Routing Service. Make quick turn prototypes and production parts in days with free standard shipping on all US orders.

CNC Routing Services

Get quotes on custom parts with our Online CNC Routing Service. Make quick turn prototypes and production parts in days with free standard shipping on all US orders.

CNC Milling Materials

-

Aluminum

Aluminum 7075 T651 and T7: Benefits include high strength, hardness, low weight, corrosion resistance, and high heat tolerance.

Aluminum

Aluminum 7075 T651 and T7: Benefits include high strength, hardness, low weight, corrosion resistance, and high heat tolerance. -

Brass

Brass C260, or cartridge brass, contains 70 percent copper and 30 percent zinc. The brass alloy has high ductility and is considered the most general purpose of all brass alloys.

Brass

Brass C260, or cartridge brass, contains 70 percent copper and 30 percent zinc. The brass alloy has high ductility and is considered the most general purpose of all brass alloys. -

Copper

Determine the size and shape of the copper material required. This includes length, width, thickness and possible special shape requirements. Detailed design drawings or instructions can be provided.

Copper

Determine the size and shape of the copper material required. This includes length, width, thickness and possible special shape requirements. Detailed design drawings or instructions can be provided.

-

Stainless Steel

Stainless Steel 304/304L and 316/316L as well as Stainless Steel 303 and Type 360 (17-4) have all proven to be high-quality options for CNC machining projects that require either milling or turning.

Stainless Steel

Stainless Steel 304/304L and 316/316L as well as Stainless Steel 303 and Type 360 (17-4) have all proven to be high-quality options for CNC machining projects that require either milling or turning. -

Alloy Steel

The solutions for product application can be customized according to the special requirements of the industry for graphite.The solutions for product application can be customized according to the special requirements of the industry for graphite

Alloy Steel

The solutions for product application can be customized according to the special requirements of the industry for graphite.The solutions for product application can be customized according to the special requirements of the industry for graphite -

Titanium

4140 Alloy Steel is the material of choice for durable, high-performance components in a variety of demanding applications

Titanium

4140 Alloy Steel is the material of choice for durable, high-performance components in a variety of demanding applications

Investment CNC Parts Process

| Tolerances | |

| Automated Factory | +/- 0.005 in. |

| Traditional Factory | +/-0.002 in. |

| Network | +/-0.001 in. |

Surface Finish and Post-Processing Options

Surface Finish Options:

Edges broken with tool marks visible

Edges broken with light bead blasting

Sharp edges (tool marks visible)

Coating and Plating Options:

Anodizing

Chromate coating

Powder coating

Network Supported

Network Supported