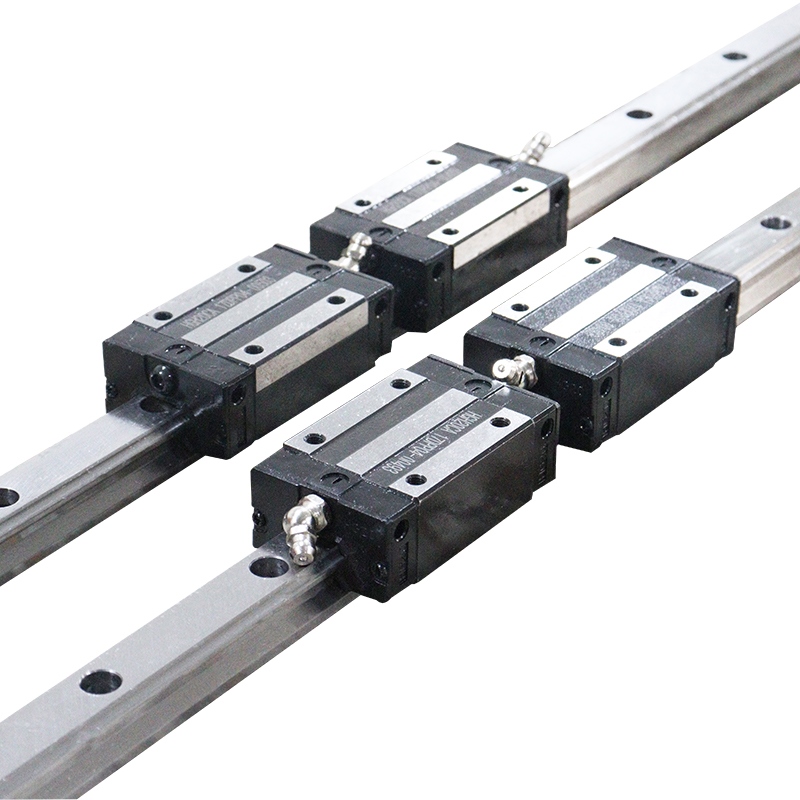

How to use linear guides efficiently?

Dec 23, 2025

The linear guide slider achieves efficient continuous operation 24 hours a day without jamming. The core reason lies in the synergistic effect of its structural design, lubrication system, and material manufacturing process, while the accompanying installation and maintenance specifications also play a crucial role. Specifically, this can be divided into the following aspects:

High-precision rolling friction structure, replacing sliding friction

The core of the linear guide is the rolling contact between the balls/rollers inside the slider and the guide rail. Compared to the surface contact of traditional sliding guides, the coefficient of friction in rolling contact is extremely low.

This structure significantly reduces resistance and heat generation during operation. Even during long-term continuous operation, excessive frictional heat will not cause component expansion and jamming. Simultaneously, the circulating design of the balls/rollers ensures that the slider receives uniform force throughout its movement, without any jamming or interruption points.

A stable and reliable lubrication system ensures long-term operation.

Lubrication is a core element in preventing jamming. Linear guides are typically equipped with a long-lasting lubrication structure:

The slider has a built-in oil reservoir and grease holder to store sufficient grease, continuously supplying oil to the ball/guide contact surfaces during operation, forming an oil film and reducing wear and resistance from direct metal-to-metal contact.

Some industrial-grade guides also support automatic lubrication systems, which can replenish lubricant at regular intervals and in measured amounts to meet the lubrication needs of 24-hour uninterrupted operation.

High-quality grease possesses high-temperature resistance, anti-aging properties, and load-bearing capacity, and will not be lost or fail due to temperature increases during prolonged operation.

High-rigidity, wear-resistant materials and surface treatment processes

The core components of the guide rails and sliders are generally made of high-carbon chromium bearing steel. After quenching, the hardness can reach HRC58~62, possessing extremely strong wear resistance and fatigue resistance. They are not prone to wear or deformation during long-term operation, avoiding jamming caused by component deformation.

The guide rail surface undergoes precision grinding, achieving a roughness of Ra0.1~0.2μm. Combined with high-precision grinding of the ball bearings, this ensures smooth movement. Some products also undergo chrome plating, nitriding, and other surface treatments to further enhance wear resistance and rust prevention, preventing jamming caused by corrosion.

Sealed and dustproof design to isolate external impurities

Impurities (such as dust and iron filings) entering the slider are a common cause of jamming. Therefore, linear guides are equipped with professional seals:

Dustproof sealing rings are installed at both ends of the slider, and a scraper plate is also provided on the outside to remove dust and debris from the guide surface, preventing them from entering the ball circulation channel;

In harsh working conditions, dust covers, bellows, and other accessories can be added to completely isolate external contaminants, ensuring the cleanliness of internal moving parts and maintaining long-term smooth operation.

Proper installation and load matching

In practical applications, correct installation accuracy and load selection are also prerequisites for 24-hour jam-free operation:

During installation, ensure the parallelism and straightness of the guide rail to avoid uneven force on the slider, uneven wear, and jamming due to installation deviations;

During selection, choose a guide rail of appropriate specifications according to the actual load to ensure that the load is within the rated range and prevent overload from causing ball deformation or jamming.

Network Supported

Network Supported