The high-performance Ball Screw features an optimized gothic-arch groove design that ensures zero-backlash precision and exceptional axial rigidity under heavy-duty loads. Our advanced surface induction hardening and precision grinding processes create an ultra-smooth raceway, significantly reducing frictional heat and extending the mechanical service life.

| Product Name | Ball Screw |

| Model Number | Customized according to drawings |

| Material | According to customer needs |

| Manufacturing Process | Rolled screw, Ground screw |

| Delivery | 14 days |

| Feature | High precision、High speed、Low noise、High efficiency |

| Specification | Value |

| Diameter | 40 |

| Lead | 10 |

| Flange | Integral |

| Thread Direction | Right Hand |

| Lead Accuracy | C3 C5 C7 |

| CSamples | Samples and catalogue available,sample express request pay by clients |

| Model | SFK,SFU,DFU,SFE,SFS,DFS,SFI,DFI,SCI |

| Application | CNC machines,machine tools,Industrial Machinery,Pringting Machine,Paper-processing machine,automatic machines,textiles machines,electronic machinery,transport machinery,Robot,etc. |

Single-nut ball screws are widely used in the following fields because of their compact structure, low cost and ability to meet medium precision and load requirements:

1.Universal Machine Compatibility: Engineered for high-precision CNC systems and machine tools, these ball screws provide the essential mechanical stability required for accurate metal cutting and positioning. Their robust design makes them equally effective in heavy-duty printing and paper-processing machinery.

2.High-Speed Automation Efficiency: Ideal for robots and automated assembly lines, our ball screws support rapid linear motion with minimal frictional heat. This ensures consistent performance in high-speed electronic and textile machinery where productivity is critical.

3.Diverse Industrial Durability: From transport machinery to specialized industrial equipment, the high-grade steel construction offers exceptional wear resistance and load-bearing capacity. The advanced sealing technology protects the internal components, extending service life in demanding factory environments.

4.Manufacturer-Direct Customization Leveraging: our large-scale factory inventory, we provide rapid 14-day delivery for both standard and customized solutions based on your technical drawings. This allows for a perfect fit across multiple sectors, ensuring a seamless replacement or upgrade for your current systems.

Product Introduction

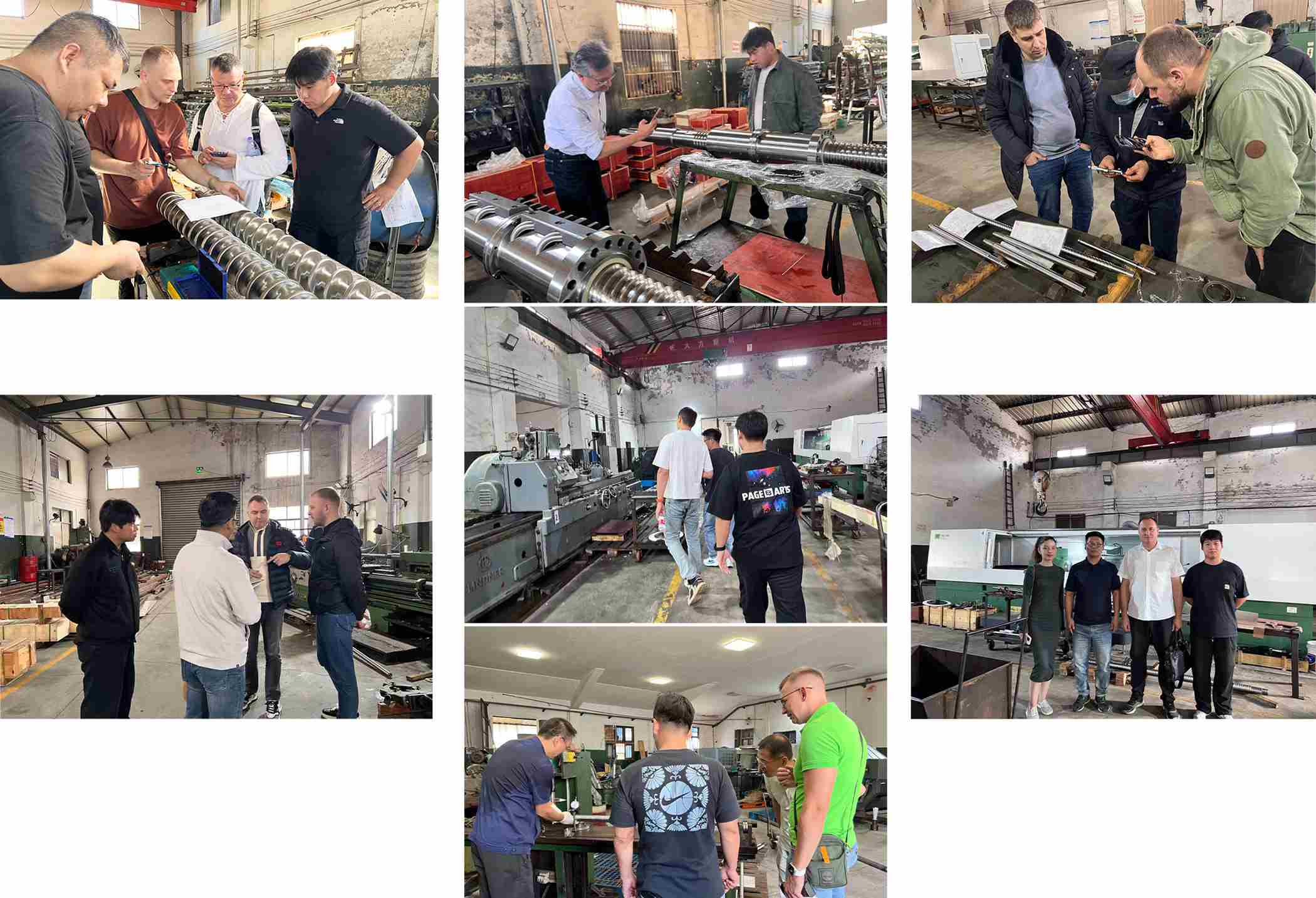

The processing of ball screw products includes the following steps:

1. Material selection: Select high-quality metal materials, such as high-quality alloy steel, for the main part of the ball screw.

2. Turning: Use a lathe to turn the metal material. First, fix the metal material on the lathe and use a cutting tool to gradually cut the material into a cylindrical work piece. This step ensures that the ball screw has a precise diameter and length.

3. Screw thread processing: Screw thread processing is performed on the outer surface of the ball screw. This requires the use of a thread tool to cut the thread line onto the ball screw so that it can be matched with other equipment.

4. Steel ball processing: Make steel balls of suitable size for rolling movement between the ball screw and the slider. Steel balls are usually made of metal materials and are precisely sized through processing processes such as grinding.

5. Assembly: Assemble the various components of the ball screw. It mainly includes placing the ball screw into the guide rail and ensuring that the steel ball is correctly assembled into the raceway between the ball screw and the slider.

6. Debugging and quality inspection: After assembly, the ball screw needs to be debugged and quality inspected. This includes checking the rolling smoothness, measuring the accuracy and size of the screw, and verifying the quality and performance of the entire ball screw system.

7. Surface treatment: As needed, the ball screw can be surface treated, such as chrome plating, blackening, etc., to improve its wear resistance and corrosion resistance.

Introduction to the manufacturing process and capabilities

Production facilities

Production facilities

Processing technology

Processing technology

Quality management

Quality management

Customization capabilities

Customization capabilities

Production capacity and delivery capabilities

Production capacity and delivery capabilities

Technological innovation

Technological innovation

Copyright @ 2024 Nanjing Chunxin Automation Equipment Co., Ltd., Limited. All Rights Reserved.

Network Supported

Network Supported