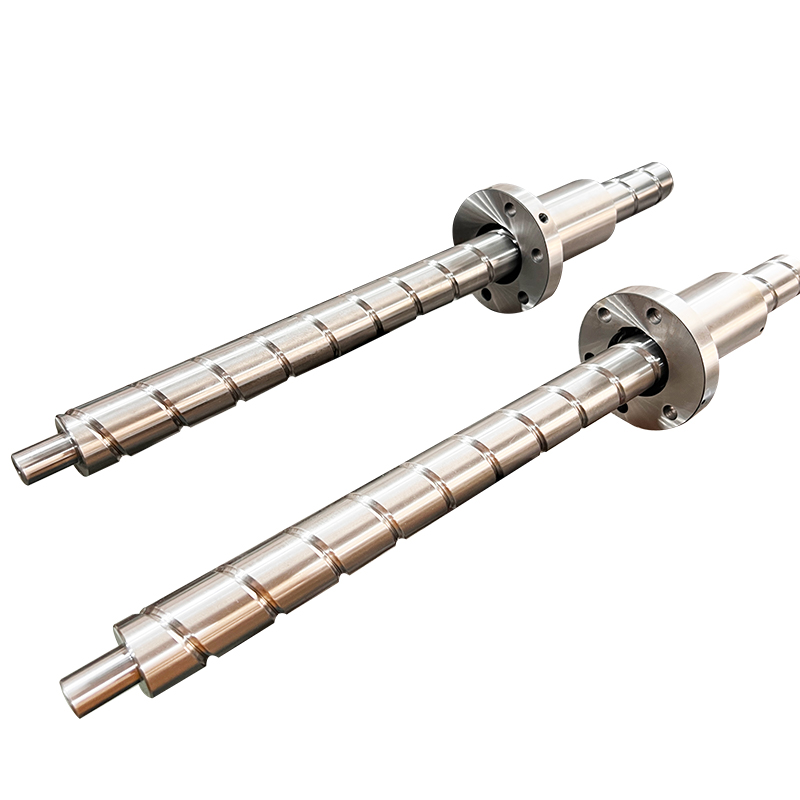

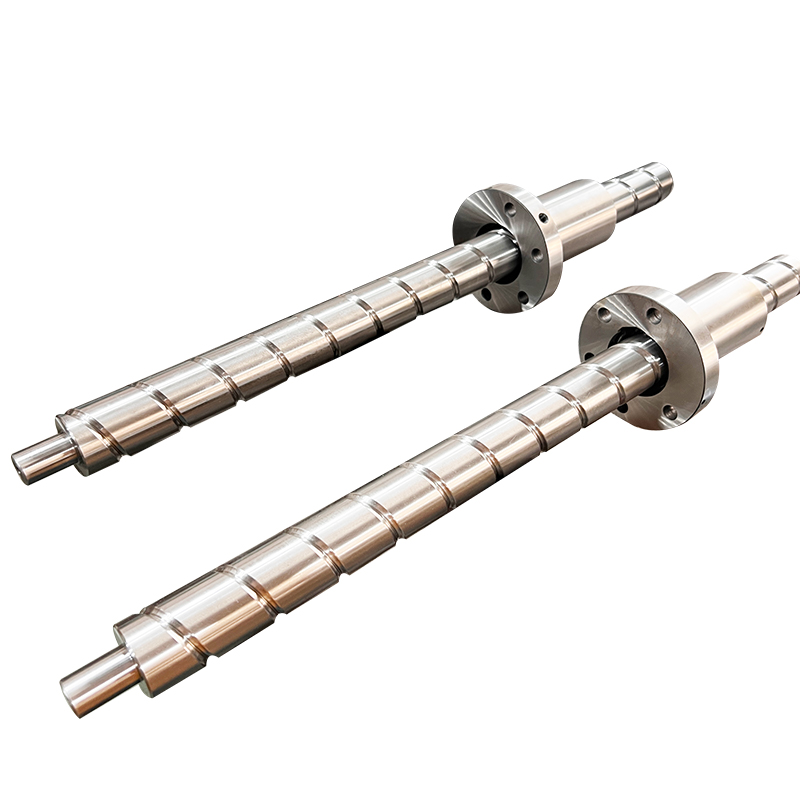

The ball screw/spline contains the ball screw grooves and the ball spline groove crossing one another. The nuts of the ball screw and the ball spline have dedicated support bearings directly embedded on the circumference of the nuts.The ball screw/spline is capable of performing three (rotational, linear, and spiral) modes of motion with a single shaft by rotating or stopping the spline nut.

| Product Name | Ball Screw |

| Model Number | Customized according to drawings |

| Material | According to customer needs |

| Manufacturing Process | Rolled screw, Ground screw |

| Delivery | 14 days |

| Feature | High precision、High speed、Low noise、High efficiency |

| Specification | Value |

| Diameter | 50 |

| Lead | 10 |

| Flange | Integral |

| Thread Direction | Right Hand |

| Lead Accuracy | C5 C3 |

| Size customize | Available |

| Samples | Samples and catalogue available,sample express request pay by clients |

| Application | CNC machines,machine tools,Industrial Machinery,Pringting Machine,Paper-processing machine,automatic machines,textiles machines,electronic machinery,transport machinery,Robot,etc |

A ball screw is a mechanical transmission device used to convert rotary motion into linear motion. The thread grinding of a ball screw is a manufacturing process requiring strict control and specialized technology. Below are the general steps and some precautions for ball screw thread grinding:

Thread Cutting Process Planning: Determine the thread specifications and requirements, including parameters such as pitch and thread angle. Design the grinding process based on these parameters.

Machine Tool Preparation: Select an appropriate CNC grinder or other specialized equipment for thread grinding. Ensure the machine tool's accuracy and stability.

Workpiece Clamping: Fix the ball screw to the machine tool, ensuring a secure clamping to prevent vibration and deviation during grinding.

Grinding Operation: Use a suitable grinding stone for thread grinding, controlling the feed rate, depth of cut, and rotational speed to ensure the machining quality and surface roughness meet requirements.

Lubrication and Cooling: Maintain proper lubrication and cooling during grinding to reduce wear and improve machining efficiency.

Quality Inspection: After grinding, a rigorous quality inspection is required to check whether the thread accuracy, surface quality, and dimensions meet design requirements.

Surface Treatment: The surface of the ball screw can be treated as needed, such as chrome plating or nitriding, to improve its wear resistance and service life.

Precision Lubrication: When installing and using the ball screw, ensure the use of an appropriate lubricant to guarantee its normal operation and performance.

It should be noted that ball screw thread grinding is a highly technical process requiring precise equipment and operation to ensure the quality and performance of the ball screw. For detailed processing procedures and parameters, please consult us.

Single-nut ball screws are widely used in the following fields because of their compact structure, low cost and ability to meet medium precision and load requirements:

1. General industrial equipment

Automated production lines, packaging machinery, printing equipment.

2. CNC machine tools and processing equipment

Economic CNC machine tools, EDM machines.

3. Medical and laboratory equipment

Medical imaging equipment: Translation of CT machine slip ring brackets requires low noise and stability.

Laboratory instruments: Rely on the self-locking property of the screw (with brakes).

4. Automobiles and transportation

Automotive electronics: Electric window lifters, seat adjustments (dustproof seal design).

Rail transportation: Subway door switch transmission, which needs to pass vibration and durability tests.

Single-nut ball screws occupy the mainstream market in light and medium loads, medium and low speeds and conventional precision scenarios due to their cost-effectiveness.

The processing of ball screw products includes the following steps:

1. Material selection: Select high-quality metal materials, such as high-quality alloy steel, for the main part of the ball screw.

2. Turning: Use a lathe to turn the metal material. First, fix the metal material on the lathe and use a cutting tool to gradually cut the material into a cylindrical work piece. This step ensures that the ball screw has a precise diameter and length.

3. Screw thread processing: Screw thread processing is performed on the outer surface of the ball screw. This requires the use of a thread tool to cut the thread line onto the ball screw so that it can be matched with other equipment.

4. Steel ball processing: Make steel balls of suitable size for rolling movement between the ball screw and the slider. Steel balls are usually made of metal materials and are precisely sized through processing processes such as grinding.

5. Assembly: Assemble the various components of the ball screw. It mainly includes placing the ball screw into the guide rail and ensuring that the steel ball is correctly assembled into the raceway between the ball screw and the slider.

6. Debugging and quality inspection: After assembly, the ball screw needs to be debugged and quality inspected. This includes checking the rolling smoothness, measuring the accuracy and size of the screw, and verifying the quality and performance of the entire ball screw system.

7. Surface treatment: As needed, the ball screw can be surface treated, such as chrome plating, blackening, etc., to improve its wear resistance and corrosion resistance.

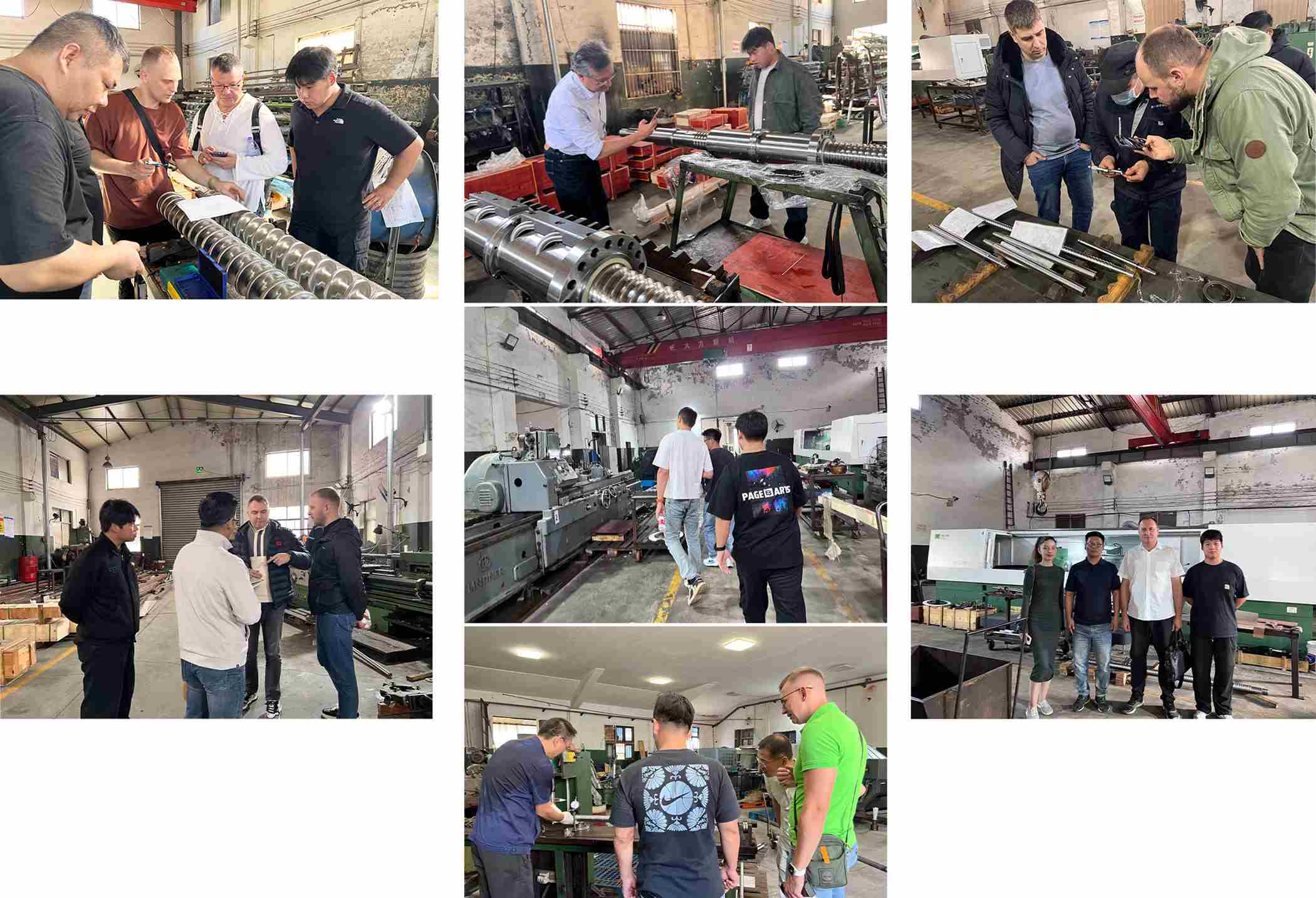

Introduction to the manufacturing process and capabilities

Production Facilities

Production Facilities

Processing Technology

Processing Technology

Quality management

Quality management

Customization capabilities

Customization capabilities

Capability Of Delivery

Capability Of Delivery

Technological innovation

Technological innovation

For more information about ball screw informations, Please contact us!

Copyright @ 2024 Nanjing Chunxin Automation Equipment Co., Ltd., Limited. All Rights Reserved.

Network Supported

Network Supported