This high-precision SFU1605 Ball Screw Kit is engineered for superior linear motion, offering options across C3, C5, and C7 grades to meet diverse accuracy requirements. The 50mm shaft and 4mm lead ensure exceptional stability and smooth transmission under heavy loads. Crafted from premium-grade steel, this 1000mm assembly minimizes friction while maximizing service life. It is the ideal choice for CNC machinery and automation projects demanding rigorous precision and long-term reliability.

| Product Name | Ball Screw |

| Model Number | Customized according to drawings |

| Material | According to customer needs |

| Manufacturing Process | Rolled screw, Ground screw |

| Delivery | 14 days |

| Feature | High precision、High speed、Low noise、High efficiency |

| Specification | Value |

| Diameter | 25 |

| Lead | 10 |

| Flange | Integral |

| Thread Direction | Right Hand |

| Lead Accuracy | C5 |

| Transport Package | PVC Bag, Wooden Box, Full Container Export |

| Material | GCr15 Bearing steel |

| Surface Hardness | HRC58~62 |

Single-nut ball screws are widely used in the following fields because of their compact structure, low cost and ability to meet medium precision and load requirements:

1.Optimized Kinematics: The internal ball circulation system is meticulously designed to eliminate vibration, ensuring ultra-smooth movement even at high rotational speeds.

2.Superior Load Distribution: Featuring a high-load-carrying capacity, the structural geometry of the nut and screw tracks ensures uniform pressure distribution to prevent premature fatigue.

3. Minimal Frictional Torque: Advanced surface finishing significantly reduces the starting torque, allowing for high-sensitivity motion control and lower energy consumption in your motor drive systems.

4.Industrial-Grade Durability: Exceptional dust-proof sealing and high-hardness raceways provide robust protection against debris, maintaining peak precision in harsh manufacturing environments.

The processing of ball screw products includes the following steps:

1. Material selection: Select high-quality metal materials, such as high-quality alloy steel, for the main part of the ball screw.

2. Turning: Use a lathe to turn the metal material. First, fix the metal material on the lathe and use a cutting tool to gradually cut the material into a cylindrical work piece. This step ensures that the ball screw has a precise diameter and length.

3. Screw thread processing: Screw thread processing is performed on the outer surface of the ball screw. This requires the use of a thread tool to cut the thread line onto the ball screw so that it can be matched with other equipment.

4. Steel ball processing: Make steel balls of suitable size for rolling movement between the ball screw and the slider. Steel balls are usually made of metal materials and are precisely sized through processing processes such as grinding.

5. Assembly: Assemble the various components of the ball screw. It mainly includes placing the ball screw into the guide rail and ensuring that the steel ball is correctly assembled into the raceway between the ball screw and the slider.

6. Debugging and quality inspection: After assembly, the ball screw needs to be debugged and quality inspected. This includes checking the rolling smoothness, measuring the accuracy and size of the screw, and verifying the quality and performance of the entire ball screw system.

7. Surface treatment: As needed, the ball screw can be surface treated, such as chrome plating, blackening, etc., to improve its wear resistance and corrosion resistance.

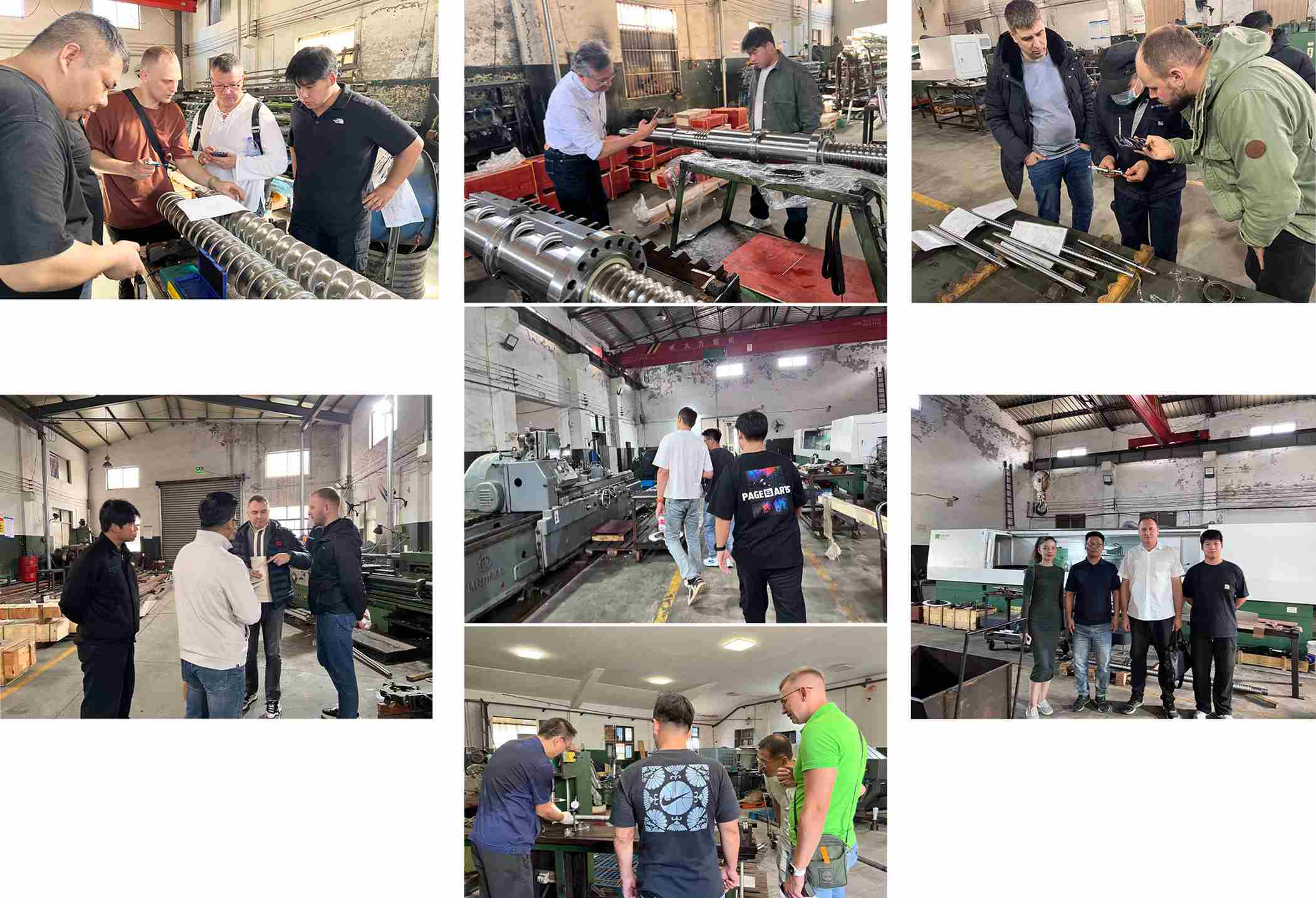

Introduction to the manufacturing process and capabilities

Production facilities

Production facilities

Processing technology

Processing technology

Quality management

Quality management

Customization capabilities

Customization capabilities

Production capacity and delivery capabilities

Production capacity and delivery capabilities

Technological innovation

Technological innovation

Q: How to Custom-made (OEM/ODM)?

A: If you have a product drawing or a sample, please send to us, and we can custom-made the as your required. We will also provide our professional advices of the products to make the design to be more realized & maximize the performance.

Q: When can I get the quotation?

A: We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

Q: How can I get a sample to check the quality?

A: After confirmation of our quoted price, you can place the sample order. The sample will be started after you sign back our detailed technical file.

Q: What's your payment terms?

A: Our payment terms is 30% deposit,balance 70% before shipment.

For more information about ball screw informations, Please contact us!

Copyright @ 2024 Nanjing Chunxin Automation Equipment Co., Ltd., Limited. All Rights Reserved.

Network Supported

Network Supported